The City of Lake Forest water system infrastructure was upgraded with a state-of-the-art membrane filtration system to produce high-quality drinking water for its customers. Following years of challenging operations and optimization efforts, the City discovered 10 years later that the Aquasource membrane filtration modules, critical to producing its drinking water, were no longer going to be manufactured.

The City Council knew that it had to quickly decide how it was going to continue to provide its customers with a reliable supply of quality drinking water. The City Council established several goals and objectives moving forward, including:

• Desire for a 14 million-gallon-per-day (MGD) cold water (0°C) treatment production

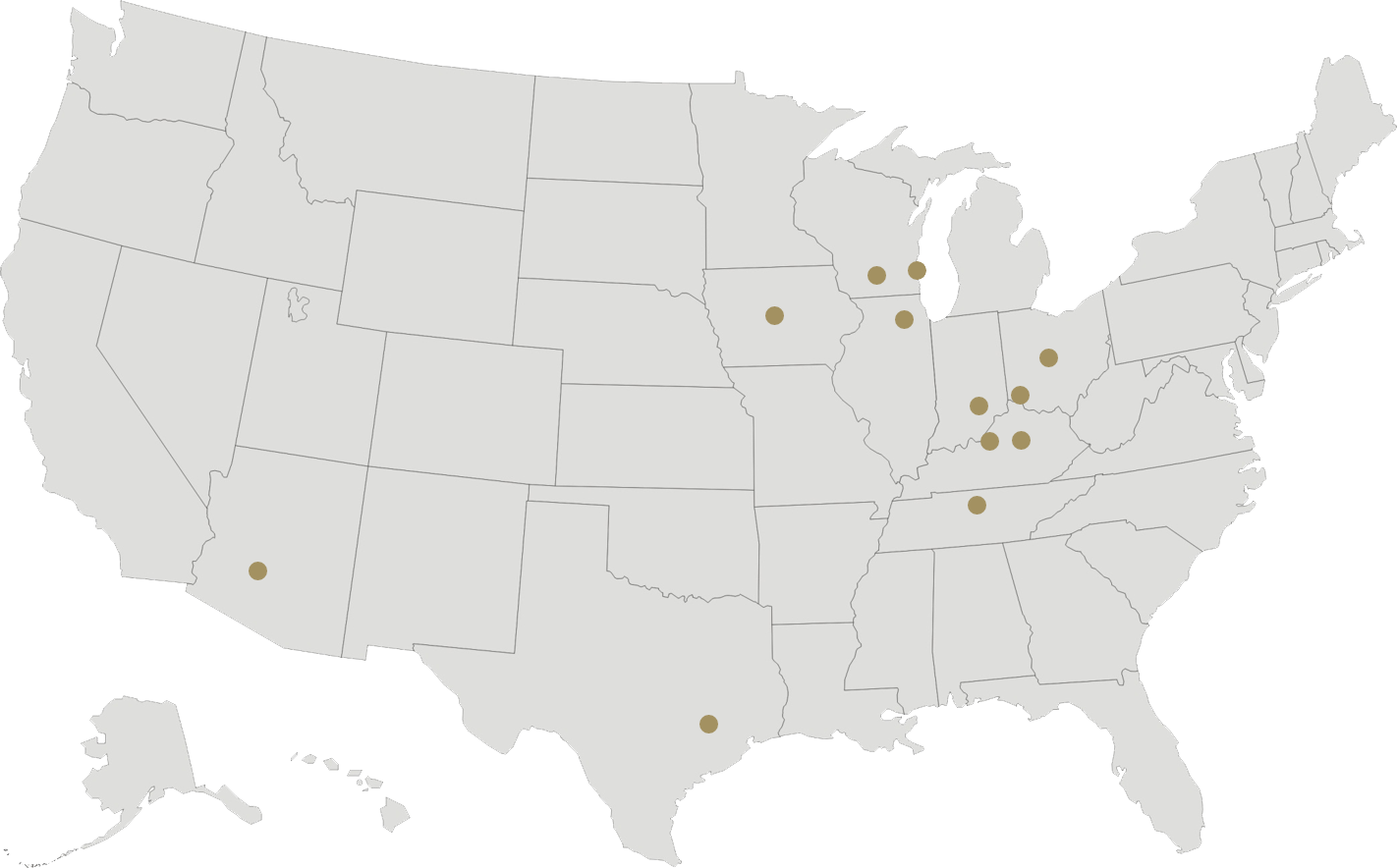

• Selection of a membrane manufacturer that would remain in the market for many years to come and with significant Lake Michigan and national experience

• Desire for process flexibility to avoid a single-source membrane module supplier

• Desire to leverage the remaining value of the existing infrastructure by incorporating as much of the existing equipment, processes, and infrastructure into the new design as possible

The City hired us as its engineer to assist in meeting its goals. After evaluating alternatives through the Water Treatment Plant Master Plan, including privatization and connection to neighboring water supplies, the decision was made to transition the City from the obsolete membrane modules to a new, more cost-effective replacement membrane system to extend the life and flexibility of its treatment process for another 20 years, with minimal increases to water rates.

2020 APWA Chicago Metro Chapter-Lake Branch Project of the Year Award Winner

Back to Project Gallery